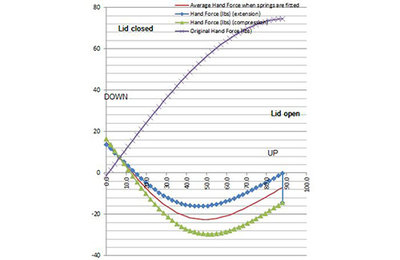

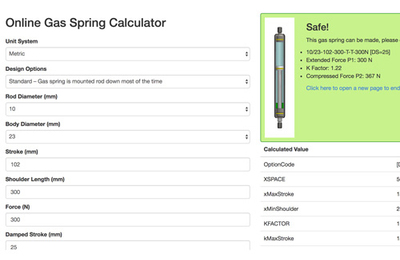

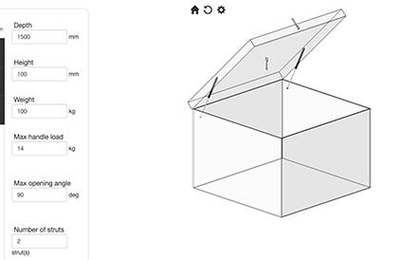

While gas springs and dampers are simple devices, the correct specification and positioning can be complex and time consuming.

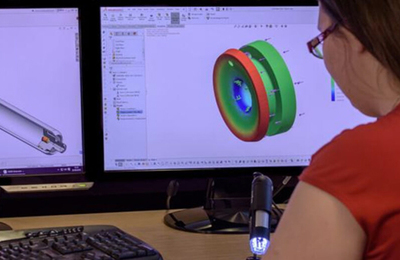

Governed by mathematically complex principles of fluid dynamics, the development of effective gas springs and dampers’ solutions requires subject matter experts and specialist equipment.

IGS takes pride in its top-class application design support services, offered by our highly trained and experienced Technical Sales and Engineering team.

When required, IGS offers a wide range of industry standard Qualification Testing Services.